|

Construction Started on 10/04/04 with the Left wing and

Aileron. My build table is a craftsman workbench with an MDF top that's

quite flat and long enough for the fuselage of this plane (65"). Each wing

panel is 45".

Here is the work area, typical mess, with the kit bags

shown. The cowl is at the rear a one piece aluminum extrusion. The

wheels are Williams Brothers, probably the last of their kind since the business

folded.

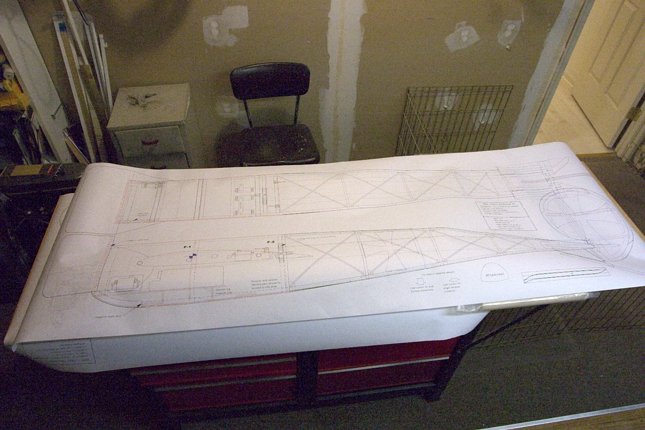

Here is one of the fuselage plan rolls, barely fits on the

table.

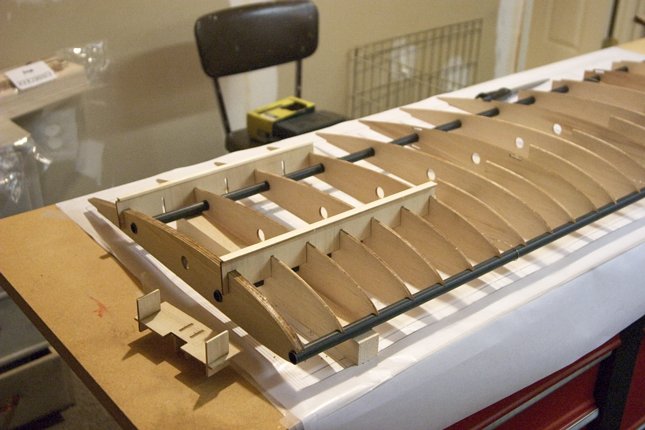

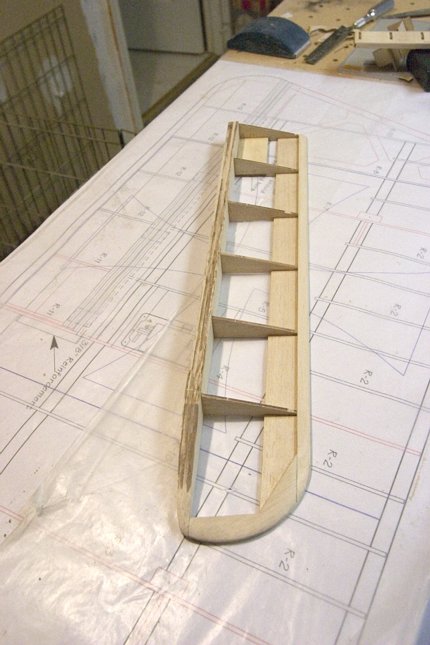

Dry fit of the wing carbon fiber tubes and all the ribs.

The root rib is a 3 part sandwich of 2 ply and 1 balsa rib.

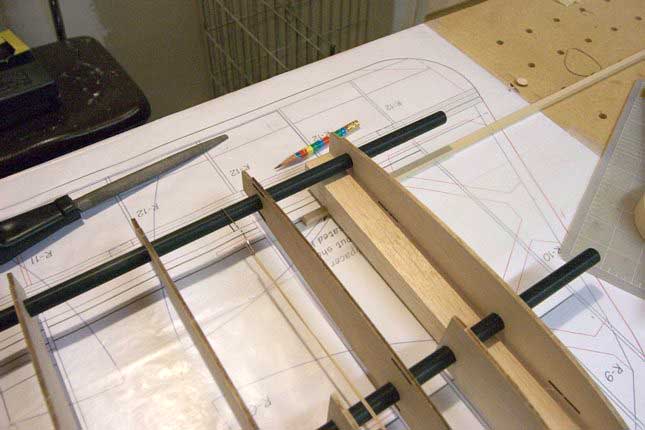

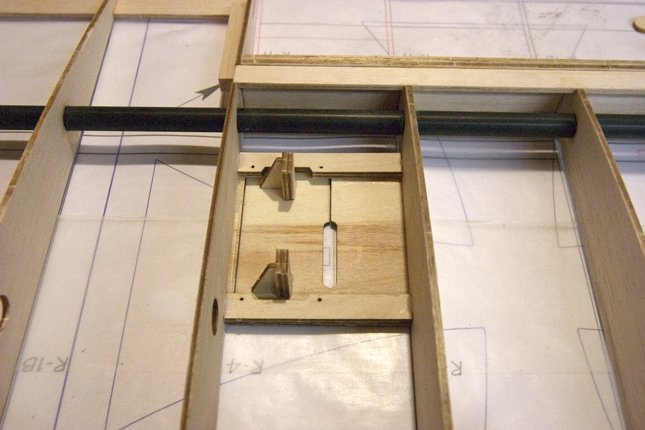

Here is how the ribs are aligned. The plywood combs

space the ribs from the root and the widget on the left is used to align the

root rib and the main spars before gluing with thin CA. The leading edge

is in place and is also a carbon fiber tube. No dings on the leading edge

on this baby!

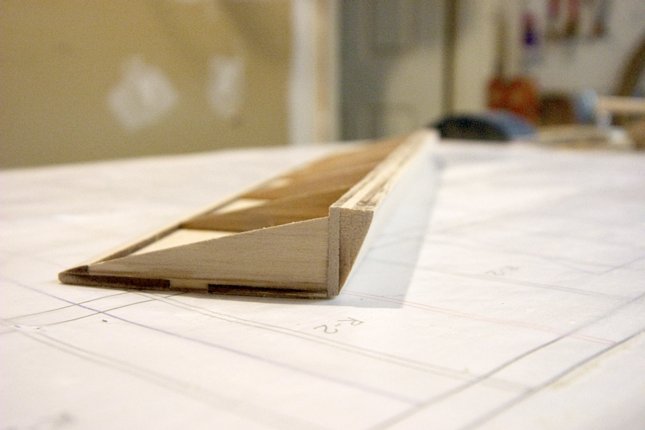

Wing washout is added with a 1/4" spacer near the tip

under the 1" square support/alignment blocks used for building the wing.

The wings are supported on the carbon tubes and float above the plan during

assembly.

Trailing edge is added

Aileron hinge attachement box is built with laminations of

four 1/8 balsa sheets.

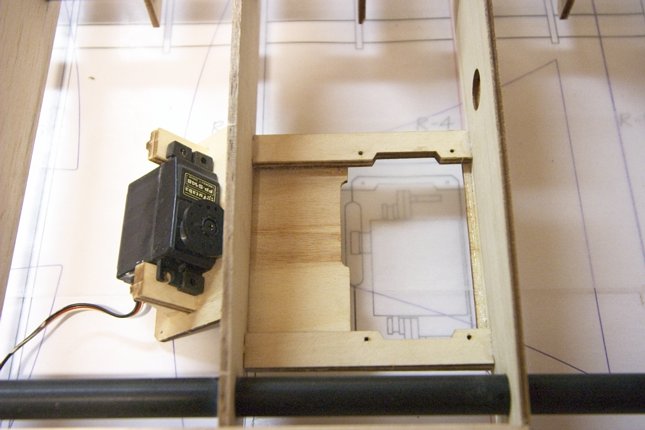

Aileron servo mounts are removeable.

These blocks are tie down points for the flying wires

which actually function to hold the wings on during flight. They are

attached to plywood ribs for strength.

Aileron assembly is sanded to shape on Oct 16th.

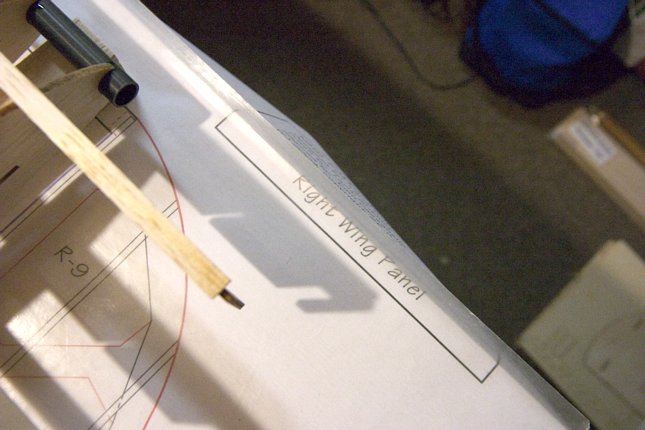

Yes I'm really starting the right wing now.

Initial buildup of the right wing ribs

Final right wing ribs glued in place on Oct 17th 2004

The Aileron hinge box is built up

The trailing edge attached

Both wings and Ailerons structure finished on 10/20/04

|